OFFICE

203605 E 45 PR SE, Kennewick, WA 99337

WAREHOUSE

11 Oak Leaf Lane, White Salmon, WA 98672

GFRC CONCRETE

GFRC (Glass fiber-reinforced concrete) ceramic consists of high-strength, alkali-resistant glass fiber embedded in a concrete & ceramic matrix. In this form, both fibers and matrix retain their physical and chemical identities, while offering a synergistic combination of properties that cannot be achieved with either of the components acting alone. In general, fibers are the principal load-carrying members, while the surrounding matrix keeps them in the desired locations and orientation, acting as a load transfer medium between the fibers and protecting them from environmental damage. The fibers provide reinforcement for the matrix and other useful functions in fiber-reinforced composite materials. Glass fibers can be incorporated into a matrix either in continuous or discontinuous (chopped) lengths.

GFRC CONCRETE

GFRC (Glass fiber-reinforced concrete) ceramic consists of high-strength, alkali-resistant glass fiber embedded in a concrete & ceramic matrix. In this form, both fibers and matrix retain their physical and chemical identities, while offering a synergistic combination of properties that cannot be achieved with either of the components acting alone. In general, fibers are the principal load-carrying members, while the surrounding matrix keeps them in the desired locations and orientation, acting as a load transfer medium between the fibers and protecting them from environmental damage. The fibers provide reinforcement for the matrix and other useful functions in fiber-reinforced composite materials. Glass fibers can be incorporated into a matrix either in continuous or discontinuous (chopped) lengths.

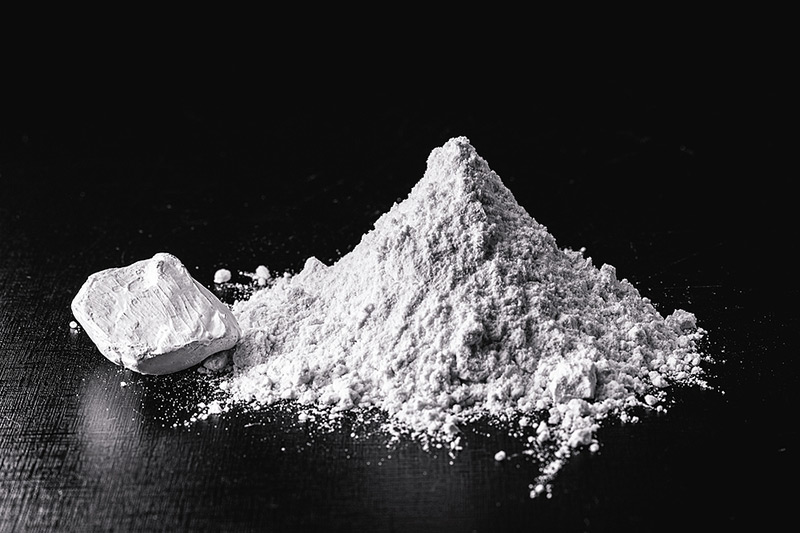

ADMIXTURES

Admixtures are materials in the form of powder or fluids that are added to the concrete to give it certain characteristics not obtainable with plain concrete mixes. Admixtures are defined as additions “made as the concrete mix is being prepared”. The most common admixtures are retarders and accelerators. In normal use, admixture dosages are less than 5% by mass of cement and are added to the concrete at the time of batching/mixing.

Accelerators speed up the hydration (hardening) of the concrete. Typical materials used are calcium chloride, calcium nitrate and sodium nitrate. However, use of chlorides may cause corrosion in steel reinforcing and is prohibited in some countries, so that nitrates may be favored, even though they are less effective than the chloride salt. Accelerating admixtures are especially useful for modifying the properties of concrete in cold weather.

Air entraining agents add and entrain tiny air bubbles in the concrete, which reduces damage during freeze-thaw cycles, increasing durability. However, entrained air entails a tradeoff with strength, as each 1% of air may decrease compressive strength by 5%. If too much air becomes trapped in the concrete as a result of the mixing process, defoamers can be used to encourage the air bubble to agglomerate, rise to the surface of the wet concrete and then disperse.

Bonding agents are used to create a bond between old and new concrete (typically a type of polymer) with wide temperature tolerance and corrosion resistance.

Corrosion inhibitors are used to minimize the corrosion of steel and steel bars in concrete.

Crystalline admixtures are typically added during batching of the concrete to lower permeability. The reaction takes place when exposed to water and un-hydrated cement particles to form insoluble needle-shaped crystals, which fill capillary pores and micro-cracks in the concrete to block pathways for water and waterborne contaminates. Concrete with crystalline admixture can expect to self-seal as constant exposure to water will continuously initiate crystallization to ensure permanent waterproof protection.

Pigments can be used to change the color of concrete, for aesthetics.

Plasticizers increase the workability of plastic, or “fresh”, concrete, allowing it to be placed more easily, with less consolidating effort. A typical plasticizer is lignosulfonate. Plasticizers can be used to reduce the water content of a concrete while maintaining workability and are sometimes called water-reducers due to this use. Such treatment improves its strength and durability characteristics.

Superplasticizers (also called high-range water-reducers) are a class of plasticizers that have fewer deleterious effects and can be used to increase workability more than is practical with traditional plasticizers. Superplasticizers are used to increase compressive strength. It increases the workability of the concrete and lowers the need for water content by 15–30%.

Retarders slow the hydration of concrete and are used in large or difficult pours where partial setting is undesirable before completion of the pour. Typical polyol retarders are sugar, sucrose, sodium gluconate, glucose, citric acid, and tartaric acid.

ADMIXTURES

Admixtures are materials in the form of powder or fluids that are added to the concrete to give it certain characteristics not obtainable with plain concrete mixes. Admixtures are defined as additions “made as the concrete mix is being prepared”. The most common admixtures are retarders and accelerators. In normal use, admixture dosages are less than 5% by mass of cement and are added to the concrete at the time of batching/mixing.

Accelerators speed up the hydration (hardening) of the concrete. Typical materials used are calcium chloride, calcium nitrate and sodium nitrate. However, use of chlorides may cause corrosion in steel reinforcing and is prohibited in some countries, so that nitrates may be favored, even though they are less effective than the chloride salt. Accelerating admixtures are especially useful for modifying the properties of concrete in cold weather.

Air entraining agents add and entrain tiny air bubbles in the concrete, which reduces damage during freeze-thaw cycles, increasing durability. However, entrained air entails a tradeoff with strength, as each 1% of air may decrease compressive strength by 5%. If too much air becomes trapped in the concrete as a result of the mixing process, defoamers can be used to encourage the air bubble to agglomerate, rise to the surface of the wet concrete and then disperse.

Bonding agents are used to create a bond between old and new concrete (typically a type of polymer) with wide temperature tolerance and corrosion resistance.

Corrosion inhibitors are used to minimize the corrosion of steel and steel bars in concrete.

Crystalline admixtures are typically added during batching of the concrete to lower permeability. The reaction takes place when exposed to water and un-hydrated cement particles to form insoluble needle-shaped crystals, which fill capillary pores and micro-cracks in the concrete to block pathways for water and waterborne contaminates. Concrete with crystalline admixture can expect to self-seal as constant exposure to water will continuously initiate crystallization to ensure permanent waterproof protection.

Pigments can be used to change the color of concrete, for aesthetics.

Plasticizers increase the workability of plastic, or “fresh”, concrete, allowing it to be placed more easily, with less consolidating effort. A typical plasticizer is lignosulfonate. Plasticizers can be used to reduce the water content of a concrete while maintaining workability and are sometimes called water-reducers due to this use. Such treatment improves its strength and durability characteristics.

Superplasticizers (also called high-range water-reducers) are a class of plasticizers that have fewer deleterious effects and can be used to increase workability more than is practical with traditional plasticizers. Superplasticizers are used to increase compressive strength. It increases the workability of the concrete and lowers the need for water content by 15–30%.

Retarders slow the hydration of concrete and are used in large or difficult pours where partial setting is undesirable before completion of the pour. Typical polyol retarders are sugar, sucrose, sodium gluconate, glucose, citric acid, and tartaric acid.

MINERAL ADMIXTURES

Inorganic materials that have pozzolanic or latent hydraulic properties, these very fine-grained materials are added to the concrete mix to improve the properties of concrete (mineral admixtures), or as a replacement for Portland cement (blended cements). Products which incorporate limestone, fly ash, blast furnace slag, and other useful materials with pozzolanic properties into the mix, are being tested and used.

Fly ash: A by-product of coal-fired electric generating plants, it is used to partially replace Portland cement (by up to 60% by mass). The properties of fly ash depend on the type of coal burnt. In general, siliceous fly ash is pozzolanic, while calcareous fly ash has latent hydraulic properties.

Ground granulated blast furnace slag (GGBFS or GGBS): A by-product of steel production is used to partially replace Portland cement (by up to 80% by mass).

Silica fume: A by-product of the production of silicon and ferrosilicon alloys. Silica fume is similar to fly ash, but has a particle size 100 times smaller. This results in a higher surface-to-volume ratio and a much faster pozzolanic reaction. Silica fume is used to increase strength and durability of concrete, but generally requires the use of superplasticizers for workability.

High reactivity metakaolin (HRM): Metakaolin produces concrete with strength and durability similar to concrete made with silica fume. While silica fume is usually dark gray or black in color, high-reactivity metakaolin is usually bright white in color, making it the preferred choice for architectural concrete where appearance is important.

Carbon nanofibers can be added to concrete to enhance compressive strength and gain a higher Young’s modulus, and also to improve the electrical properties required for strain monitoring, damage evaluation and self-health monitoring of concrete. Carbon fiber has many advantages in terms of mechanical and electrical properties (e.g., higher strength) and self-monitoring behavior due to the high tensile strength and high electrical conductivity.

MINERAL ADMIXTURES

Inorganic materials that have pozzolanic or latent hydraulic properties, these very fine-grained materials are added to the concrete mix to improve the properties of concrete (mineral admixtures), or as a replacement for Portland cement (blended cements). Products which incorporate limestone, fly ash, blast furnace slag, and other useful materials with pozzolanic properties into the mix, are being tested and used.

Fly ash: A by-product of coal-fired electric generating plants, it is used to partially replace Portland cement (by up to 60% by mass). The properties of fly ash depend on the type of coal burnt. In general, siliceous fly ash is pozzolanic, while calcareous fly ash has latent hydraulic properties.

Ground granulated blast furnace slag (GGBFS or GGBS): A by-product of steel production is used to partially replace Portland cement (by up to 80% by mass).

Silica fume: A by-product of the production of silicon and ferrosilicon alloys. Silica fume is similar to fly ash, but has a particle size 100 times smaller. This results in a higher surface-to-volume ratio and a much faster pozzolanic reaction. Silica fume is used to increase strength and durability of concrete, but generally requires the use of superplasticizers for workability.

High reactivity metakaolin (HRM): Metakaolin produces concrete with strength and durability similar to concrete made with silica fume. While silica fume is usually dark gray or black in color, high-reactivity metakaolin is usually bright white in color, making it the preferred choice for architectural concrete where appearance is important.

Carbon nanofibers can be added to concrete to enhance compressive strength and gain a higher Young’s modulus, and also to improve the electrical properties required for strain monitoring, damage evaluation and self-health monitoring of concrete. Carbon fiber has many advantages in terms of mechanical and electrical properties (e.g., higher strength) and self-monitoring behavior due to the high tensile strength and high electrical conductivity.